Weighing

System

The dribble batch hopper

consists of a four (4) compression type load cell weighing system with

digital read out (DRO). The DRO is mounted in an unobstructed

location for the loader to easily monitor during filling. Remote

displays with visually larger readings can be provided as an option.

|

The

Hopper

The hopper can be constructed

in a variety of sizes and configurations. The units can be skid

mounted, portable, or ISO containerized. Standard hoppers include

a pneumatic inching type gate, manual air over air gate controls, and

a pneumatic vibrator with air over air controls. The hopper can

be designed with electric over air controls and supplied with a mounted

air compressor. |

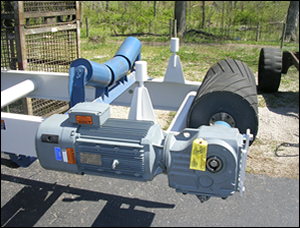

Conveyer

& Other Systems

The transfer conveyor loads

the material into the mixer truck or other mixing device. The

conveyor can be supplied with a diesel engine as a power source.

Water metering and discharge systems can be supplied and mounted on

the plant.

|