|

|

|

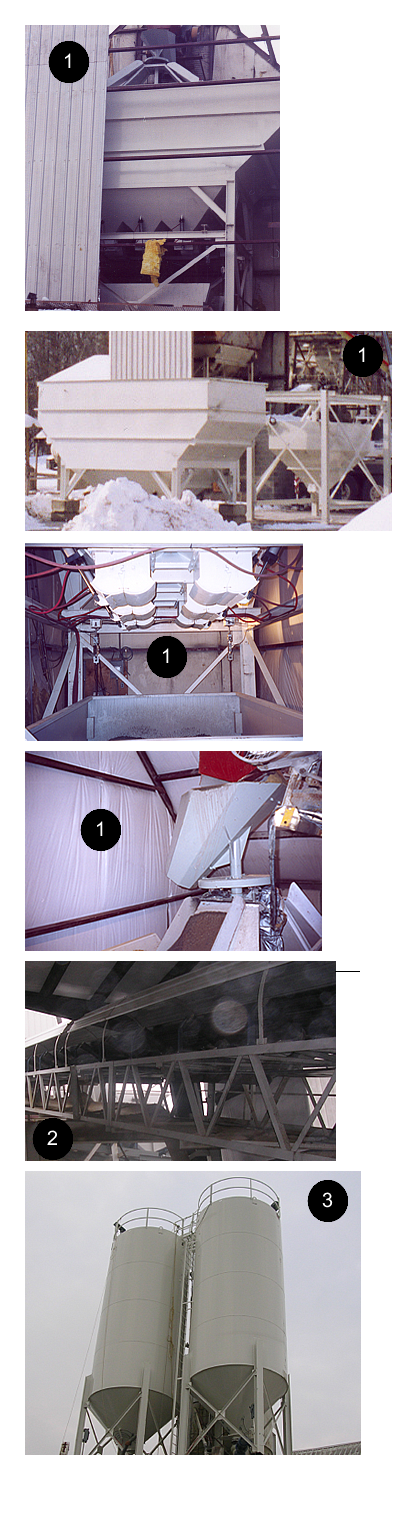

Aggregate Section & Aggregate Handling System

The aggregate section consists

of overhead aggregate storage and the aggregate weigh batcher.

Overhead aggregate storage can be designed in a vast array of optional

layout's that meet the producer's requirements for number of compartments

and storage capacity. The quantity and size of custom designed

overhead aggregate storage compartments allows for any concrete producer

to have a configuration that meets their specific needs. Overhead

aggregate bins can be supplied with replaceable abrasion resistant urethane

liners, material level indicators, moisture measuring and compensating

probes, and heating systems to accommodate cold weather concrete production.

The aggregate weigh batcher precisely weighs the aggregate materials

discharged from the overhead storage bins. Standard weigh batchers

include NTEP approved stainless steel load cells, a high speed inching

type discharge gate, pneumatic vibrator, and test weight hanging brackets.

Multiple and live bottom weigh batchers are available and all can be

supplied with abrasion resistant urethane liners.

Aggregate

feed systems can be designed in a variety of ways to facilitate

the transfer of ground storage to the overhead aggregate bins.

The

systems are designed based upon production requirements, site size and

topography, and budget. Some of the systems available include:

single feed conveyor with electric turnhead or shuttle conveyor, single

feed conveyors for each overhead compartment, radial stacking conveyors,

or a combination thereof. Various ground storage hopper configurations

can be customized for your particular application, including drive-over,

tunnel, and rail unloading systems. These systems can be completely

automated. Aggregate heating of ground storage is also available

for cold weather concrete production

|

|

|

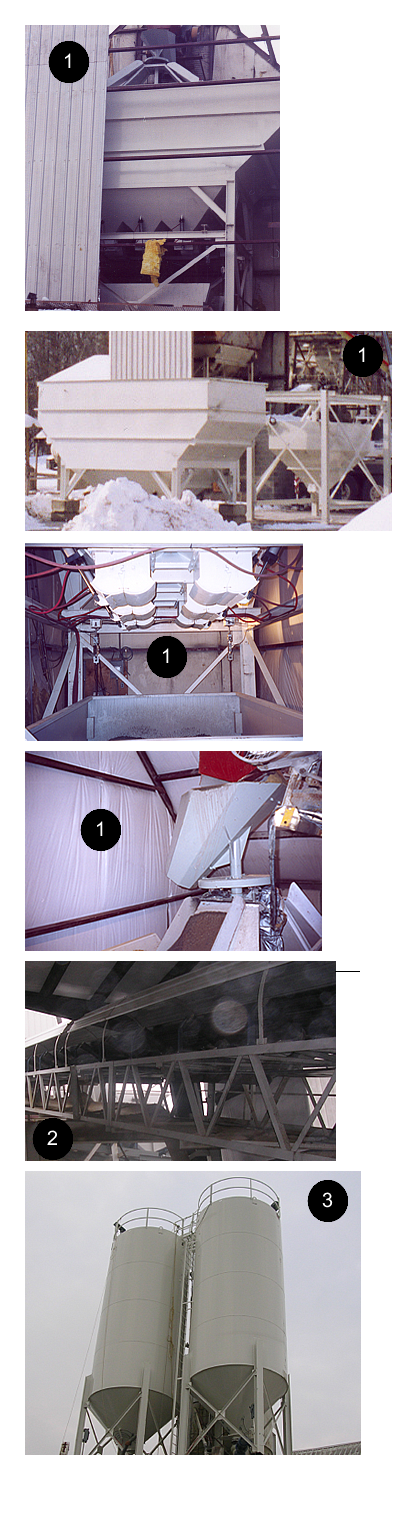

Batch

Transfer/Truck Charging Conveyor

The batch transfer conveyor

transfers the weighed aggregate materials from the aggregate weigh batch

to the mixer truck. Attached to the conveyor is an abrasion resistant

urethane lined truck charging hopper that facilitates controlled loading

into the truck. The batch transfer conveyor is sized to accommodate

your production requirements and truck loading characteristics.

|

|

|

Cement

Section

The cement section consists

of bulk storage cementitious materials storage and the cement weigh

batcher. Bulk storage cementitious storage can be configured as

single units, multi-compartment, or multiple silo arrangements.

Individual and multi-compartment silo sizes range from 200 BBL's to

2,500 BBL's. Larger bolt-together units are also available.

Storage capacities can be tailored to your production requirements.

The cement weigh batcher provides precise weighing for the plants cementitious

materials. Standard components include NTEP approved stainless

steel load cells, pneumatic inching type discharge valve, aeration,

pneumatic vibrator, and test weight hanging brackets. Multiple cementitious

materials weigh batchers can be provided to increase throughput, prevent

cross-contamination, and preserve color sensitive end products.

|

Water,

Air, & Electrical Systems

Plant mounted water, air,

and electrical systems are supplied with all transit mix plants and

are sized according to your production requirements. Various configurations

for batch water include: water meter, water meter with holding

tank, and a water weigh batcher with holding tank. The air system

that powers the plant solenoid valves and actuators is supplied by an

air compressor that is appropriately sized for each plant. The

electrical system contains the pre-wired motor control panel, main disconnect,

and transformer for all primary and control devices; requiring a single

power source connection. The electrical system can be configured

to accommodate international voltage requirements and all interconnecting

primary and control wiring can be provided with pin and sleeve connections

to facilitate quick installation.

Batch

Plant Control

The control functions of

the batch plant can be operated via a manual push button panel or through

a computer

controlled automation system. A basic manual push button

panel requires the operator to manually control each function of the

batching process. A fully automated computer control system can

complete an entire batching cycle with the push of a single button.

Fully automated plants can be independently operated of the computer

system via a backup manual panel.

Contact

Us for more information about transit mix concrete batch plants.

|

© Copyright 2012 National Concrete

Corporation

|